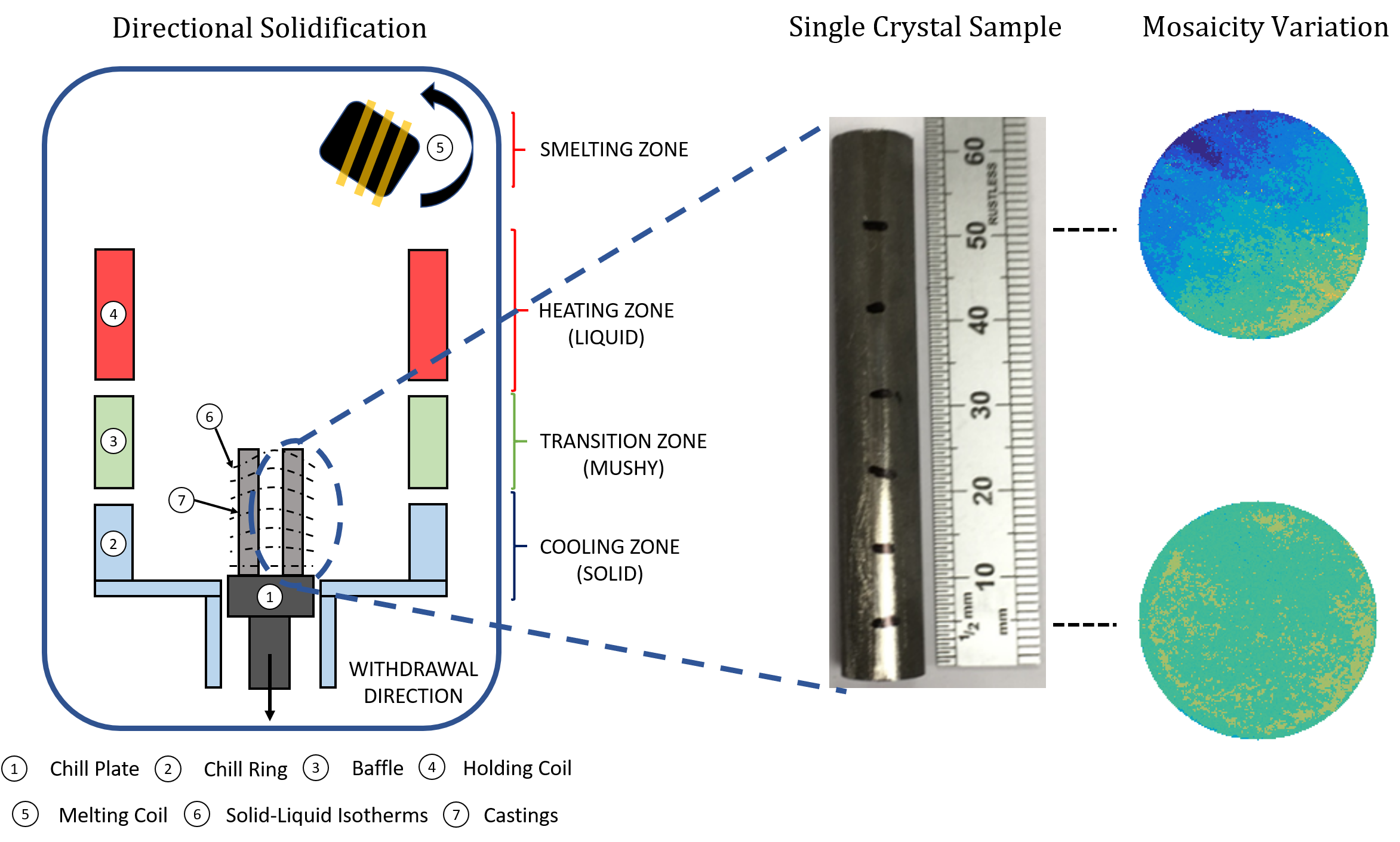

For the first time, time-of-flight energy-resolved neutron imaging has been used to understand and visualise the inside of metallic single crystals. These metallic single crystals are used in gas turbine engines to improve their mechanical properties at high temperatures. However, trying to make them is very challenging.

The aim is to produce crystals that are large enough to be practical, but where all of the regions in the internal structure are all aligned in the same direction. A common issue with the crystals used in aerospace applications is that some regions are tilted with respect to the others, like in a mosaic, and this can affect the mechanical properties.

Although there were suggestions about the cause of this tilting, until now it was impossible to see inside the crystals and find out exactly what was happening. Thanks to new software developments and the unique set up of the IMAT instrument, researchers have finally been able to take a look inside the crystals to work out what is going on.

The samples in this study, published in Scientific Reports, were brought to ISIS by Rolls-Royce Plc, in collaboration with scientists from the University of Leicester. By using the new method of time-of-flight energy-resolved neutron imaging, they were able to map the tilting seen in different areas of the crystals.

They found a twisted structure to this tilting, suggesting a spiral solidification of the crystal during manufacture. This precise measurement establishes IMAT as a fundamental characterisation tool for studying the structure and properties of these materials in the future. In fact, the group have already returned to ISIS to continue their experiments on other samples.

Schematic sample preparation geometry and Lowest transmission wavelength Bragg-dip distribution maps. Credit: Joel Strickland

"IMAT provides the foundation for understanding mosaicity within single crystals." Explains Joel Strickland, one of scientists working on this pioneering research. "Our recent work is fundamental for the ultimate aim of my PhD, which is to understand the relationship between single crystal growth and mosaicity related defects within turbine blades. In fact, the next step in our project is to compare the mosaicity maps created from IMAT with scanning electron images of turbine blade segments for exactly that purpose."

He adds; "We hope to advance the fundamental understanding behind how changes in material processing can influence mosaicity at microscopic and macroscopic length scales. This is of great interest to Rolls-Royce Plc, as mosaicity decreases a turbine blades high temperature performance, which ultimately results in a reduction in jet engine efficiency through lower turbine entry temperatures. Further, any misorientation related defects are a major cause of turbine blade non-conformance and scrappage."

Dr Genoveva Burca, beamline scientist on IMAT says; "With this study done for the first time on IMAT we turned a new page in the advancement of single crystal Ni-base superalloys research and showed once again the versatility and the potential of IMAT capabilities."

Related publication: 2D single crystal Bragg-dip mapping by time-of-flight energy-resolved neutron imaging on IMAT@ISIS, Sci Rep 10, 20751 (2020), DOI: 10.1038/s41598-020-77572-3

Authors: J Strickland, K Tassenberg, G Sheppard, B Nenchev, S Perry, J Li, H Dong (University of Leicester), G Burca (ISIS), J Kelleher (ISIS), S Irwin (Rolls-Royce Plc)