In the petrochemical industry, the separation of propylene from propane is an important and challenging process because they have almost identical molecular sizes. The current process of cryogenic distillation is one of the most energy demanding processes in the whole refinery. An alternative would be using metal-organic frameworks, MOFs, which can be modified to have different functional groups and pore sizes. Balancing selectivity and adsorption capacity is challenging, with an improvement in one often hindering the other.

In the petrochemical industry, the separation of propylene from propane is an important and challenging process because they have almost identical molecular sizes. The current process of cryogenic distillation is one of the most energy demanding processes in the whole refinery. An alternative would be using metal-organic frameworks, MOFs, which can be modified to have different functional groups and pore sizes. Balancing selectivity and adsorption capacity is challenging, with an improvement in one often hindering the other.

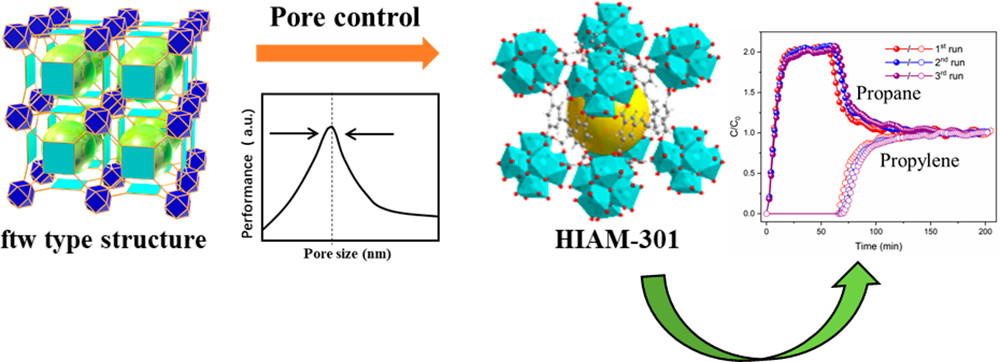

A group of researchers has designed a new MOF with a distored pore structure, HIAM-301, which shows the highest adsorption capacity for propylene with the exclusion of propane. Their study used neutron diffraction and inelastic neutron scattering to study the binding interactions of the propylene inside the pores. The results not only demonstrate the high performance of a new material, but also informs the design of future gas storage and separation candidates.

Image: Distortion of the pore structure in HIAM-301 has resulted in efficient separation of propane and propylene under dynamic flow conditions.

Further Information:

Related publication: Pore Distortion in a Metal-Organic Framework for Regulated Separation of Propane and Propylene, J. Am. Chem. Soc. 2021, 143, 46, 19300–19305 DOI:10.1021/jacs.1c10423