The DEMOnstration power plant, DEMO, is currently in design, and will take fusion from a science-driven, lab-based exercise to an industry-driven programme that will produce electricity for the grid. Because of this commercial focus, it's important that there is a way to non-destructively inspect and certify all the reactor components to ensure they are able to meet regulatory standards even after prolonged periods of use.

The divertor target in a fusion reactor is one of the most delicate components and it is subject to extremely harsh conditions. It is repeatedly bombarded with ions of the different hydrogen isotopes, helium, and neutrons produced in the fusion process. These cause direct particle damage and create a huge amount of heat, with the divertor regularly receiving heating fluxes of 10 MW/m2 during normal operation. The design of divertor target being developed for DEMO is made of tungsten armour blocks threaded onto a CuCrZr cooling pipe separated by a copper interlayer running through the middle, as shown above right.

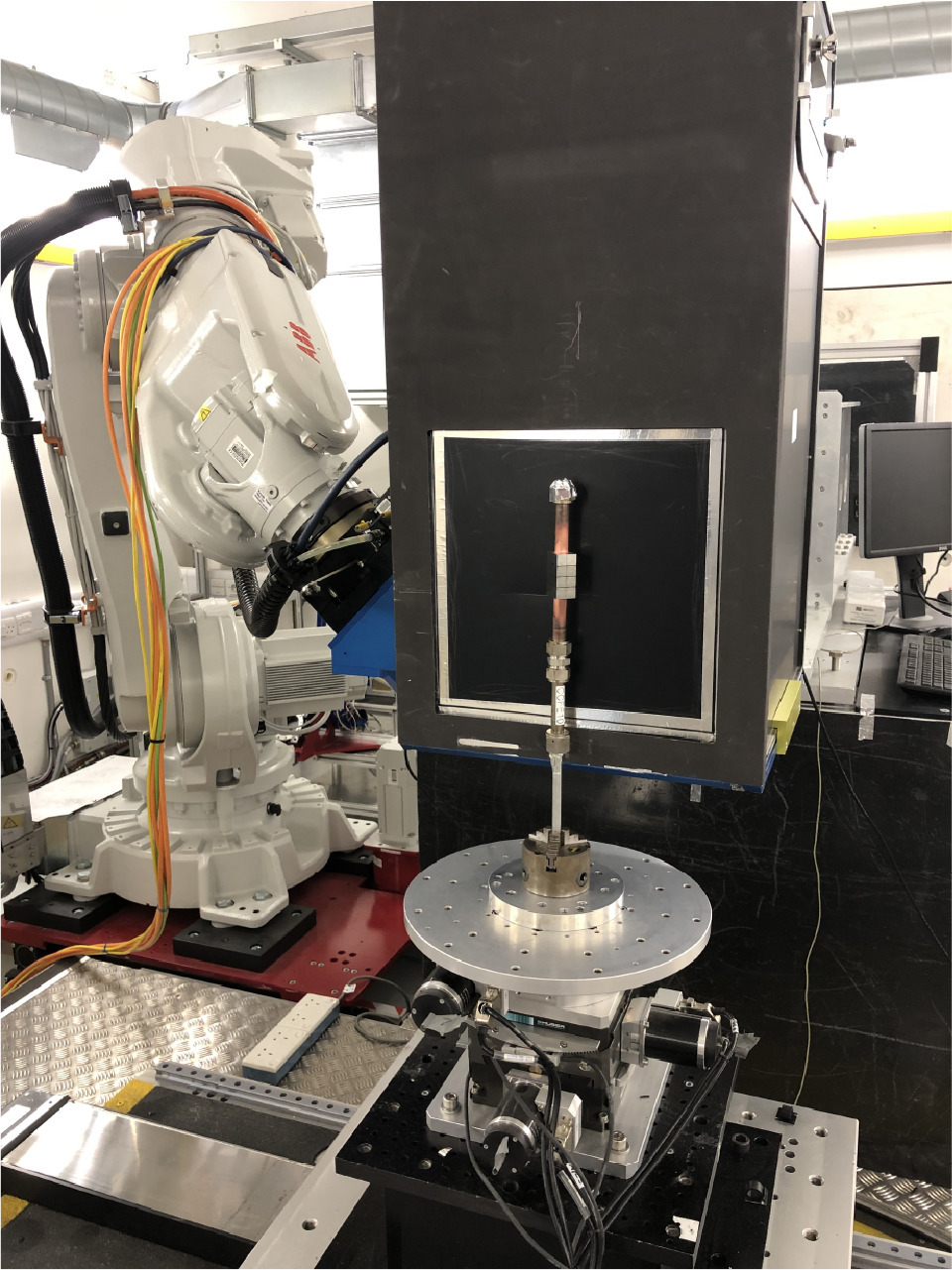

The presence of these heavy metals makes it very difficult to examine using X-rays technique due to the lack of transmission of the beam. However, neutrons do not interact with matter in the same way as X-rays, making them well suited for investigating defects within heavy metal structures. A recent study, published in Fusion Engineering and Design, confirms that neutron tomography can be used to assess the structural integrity of divertor targets.

“This gives us an extra tool in our portfolio of inspection technologies," says lead researcher Triestino Minniti from UKAEA; “we can see defects as small as a few hundred micrometres across."

By measuring the divertor mock-ups both before and after it had been through the equivalent of 100 fusion cycles, the group were able to see if their design was suitable for application in a real reactor. Triestino explains; “We saw no defects develop in the material during cycling. Therefore this study is important is showing not only that the technique is suitable for measuring these components non-destructively, but that the design itself is reliable with such large number of high heat flux cycles."

Neutron tomography setup at the IMAT beamline

Further information

The full paper can be found online at DOI: 10.1016/j.fusengdes.2021.112661