Have you ever wondered what makes up the paint on your walls? An emulsion paint consists of a polymer resin, dispersed in a water medium, where the water accounts for a large proportion of the coating. With the desire to make paints more eco-friendly the industry now mostly uses water-based emulsion paints where possible, rather than solvent based ones (which often release undesirable volatile organic compounds). One area in which this transition is more difficult is in anti-corrosion coatings. Materials and surfaces that rust due to water exposure tend to not respond well to being coated with water.

Have you ever wondered what makes up the paint on your walls? An emulsion paint consists of a polymer resin, dispersed in a water medium, where the water accounts for a large proportion of the coating. With the desire to make paints more eco-friendly the industry now mostly uses water-based emulsion paints where possible, rather than solvent based ones (which often release undesirable volatile organic compounds). One area in which this transition is more difficult is in anti-corrosion coatings. Materials and surfaces that rust due to water exposure tend to not respond well to being coated with water.

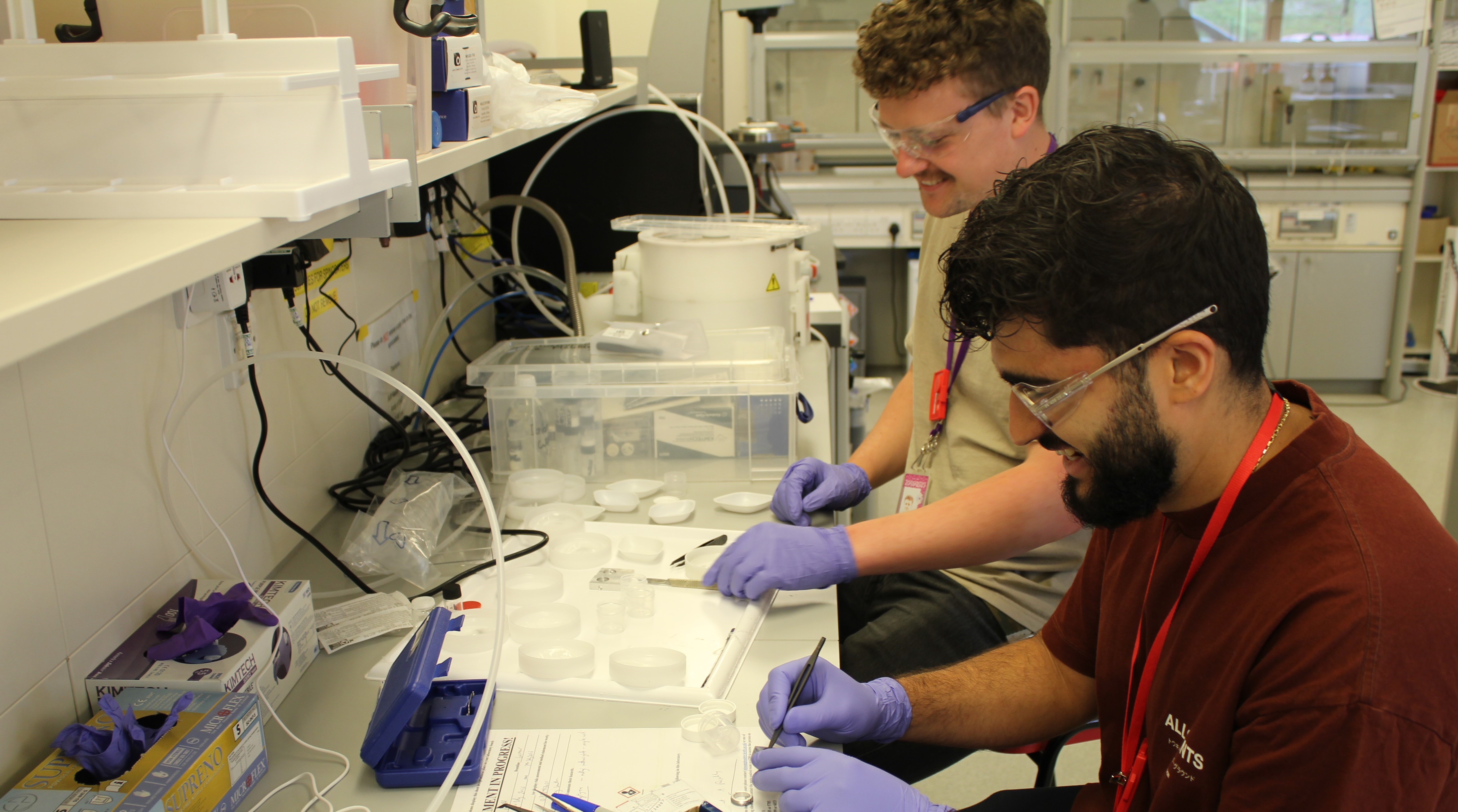

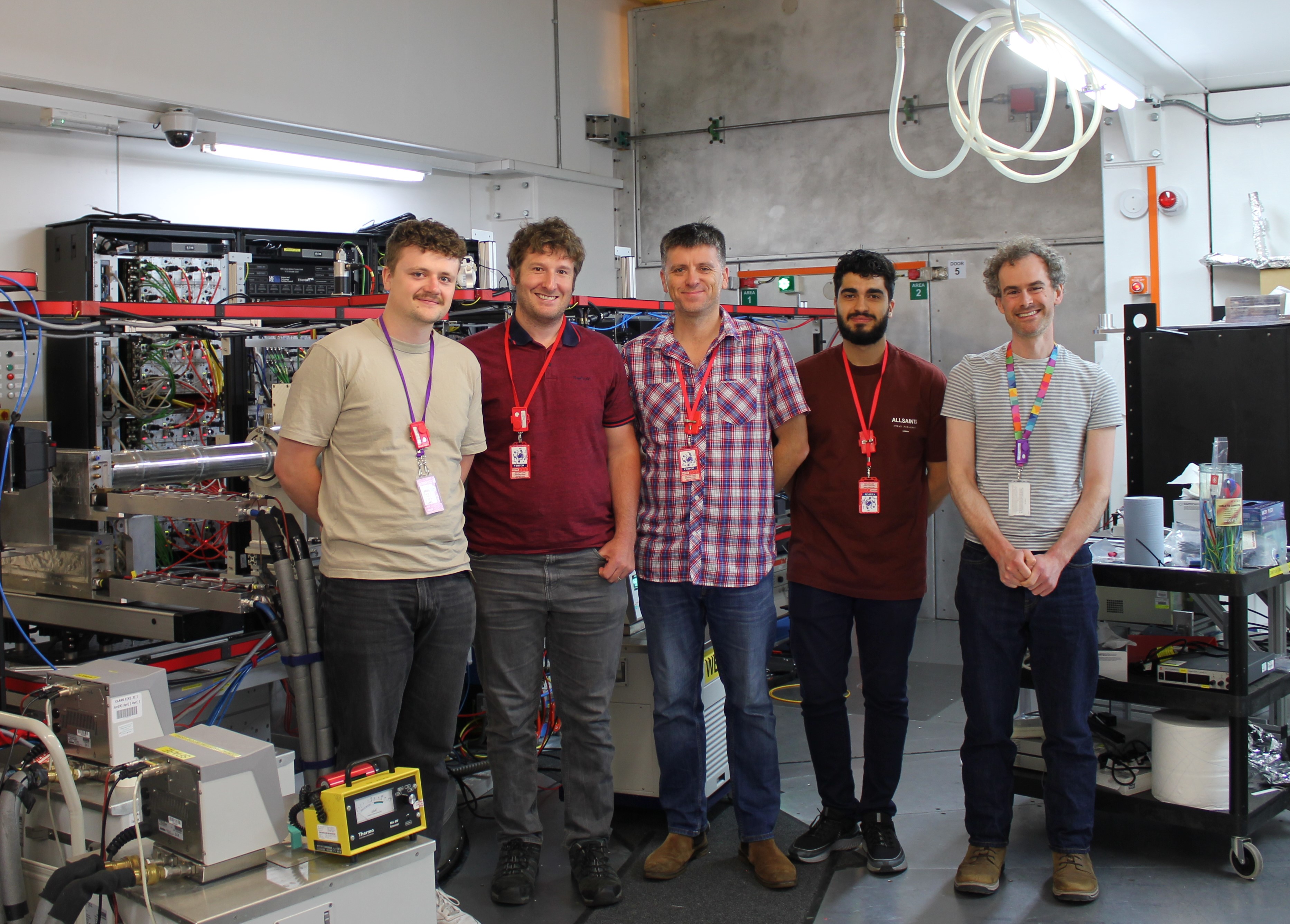

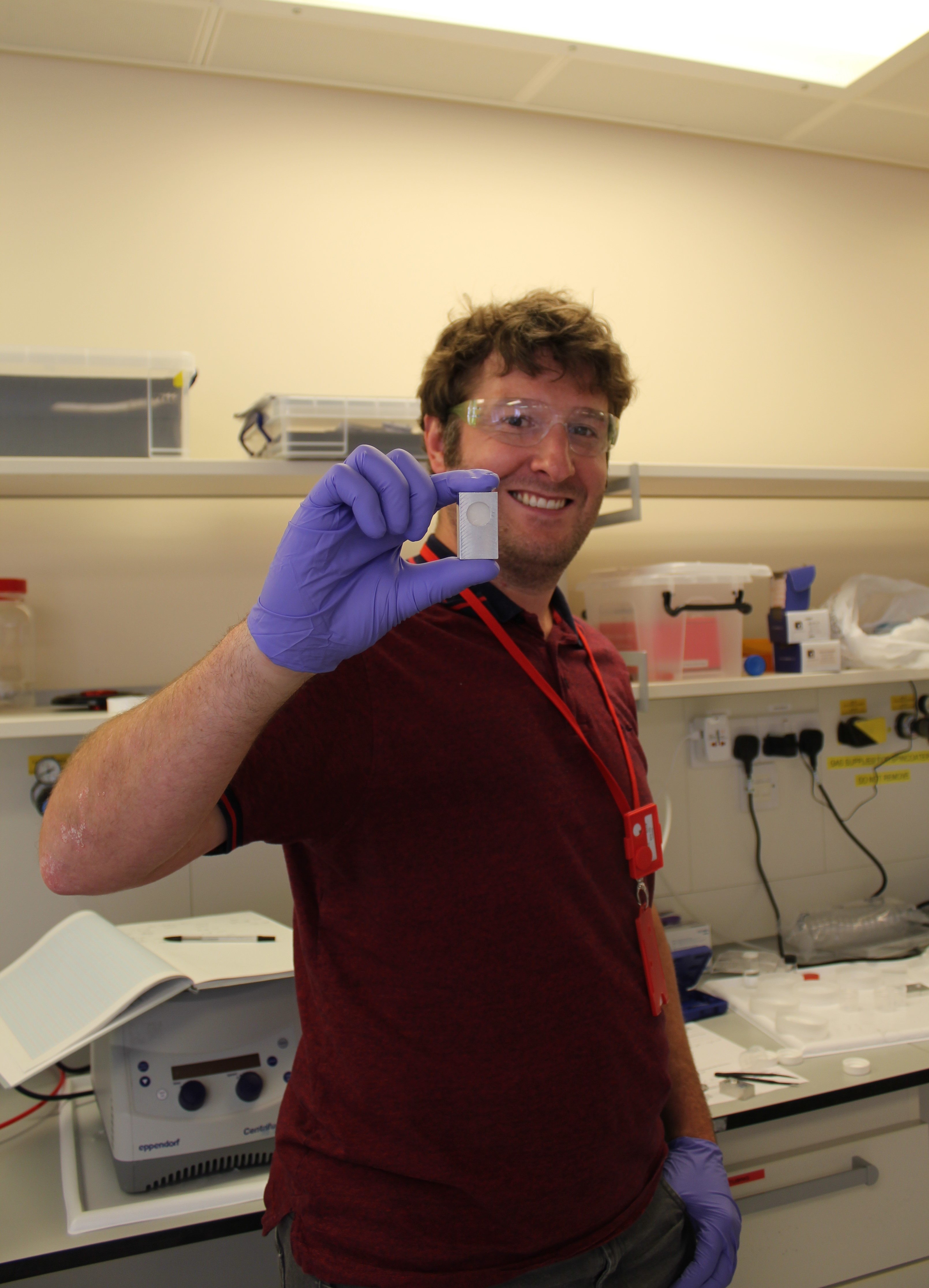

That is where researchers from the Universities of Manchester and Sheffield join the picture. They have been studying how various additives for protective coatings are affected in different environments. Through studying a series of sample coating formulations, their investigations concern how these additives interact with the polymer resin, as well as exposure to water. Studying how the structures of the samples change, will help improve our understanding of any underlying structural issues that the coatings have and how to adapt them to best suit their environment.

The typical components of a waterborne coating are; a polymeric resin (this is polymerised in the presence of surface active agents, which allow it to disperse in a water); water, which acts as a vehicle of transport for the dispersed polymer resins; and formulation additives that provide desirable properties for a coating (e.g., thickening agents, wetting agents, etc). Once coated, the polymer resin forms a protective film that protects the material from corrosion.

It is essential to understand the structure of coatings and how this can alter in different conditions to improve their properties in the future. The team came to ISIS to see how Small Angle Neutron Scattering (SANS) could help them to answer these questions. Specifically, they used our Larmor instrument to perform Spin Echo SANS (SESANS) where the neutrons are polarized. This allows them to detect changes in the sample's internal structure, providing access to a large range of length scales (from 15 nm to 10 microns). If successful, this experiment could open up a new area of research for SESANS to be used for!

There is some dispute about the future of water-based anticorrosive coatings. The main issue is that traditional oil-based paints are proven to protect surfaces for a much longer time than bio-derived alternatives. However, as with everything to do with the climate, there is always a balance to be found and the full lifecycle of a product needs to be taken into consideration. The energy required in its development, the sources of its creation (as many are bio-derived from food sources that could be used to feed people/animals), as well as considerations of how and where it degrades and if anything harmful is released, all need to be brought to the table in this discussion and compared to the traditional coating methods.

The future for this research holds much promise for anti-corrosive coatings that could not only be an everyday feature of our future lives, protecting our bridges, buildings or cars from corrosion amongst many other daily items, but this also brings an exciting future for the SESANS technique and potential new opportunities that brings to scientific research in these fields.