The Soft Matter Team have chosen to highlight some of the contributions of some of their apprentices during their four-month rotation. The Soft Matter Team can offer a wide range of activities and skills to enhance the apprentice and give them an experience to remember!

Contents:

Apprentices in the Soft Matter Team

In this issue, the Soft Matter Team wanted to highlight the excellent contributions made by

their apprentices (Corey Leaver and

Lucas Ward) in their own words. Both apprentices were working on non-ambient temperature sample environments, but showcase a broad array of projects and techniques undertaken by the Soft Matter Team.

In addition, we would like to welcome

Harry Oliver who became a full-time Soft Matter Technician in September 2022. He was previously an apprentice in the Soft Matter Team, and his work from his apprenticeship has also been highlighted.

Corey Leaver

“I’m Corey Leaver a current third year apprentice that’s in a placement with the Soft Matter department at ISIS.”

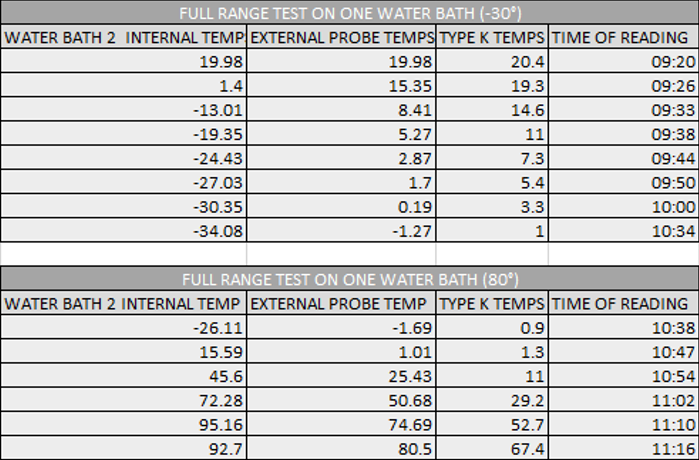

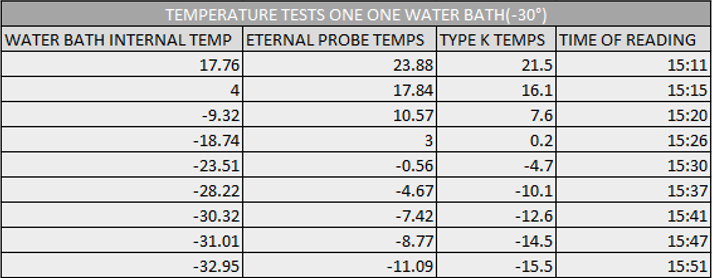

Corey was involved in testing the disparity between the temperature setpoint and achieved temperature with water baths

“In Soft Matter the use of water baths to control the temperature is frequently used. This is the same for SANS2D and ZOOM which both use water baths to control the temperature of the sample changers that they use. While trying to perform and experiment where the users wanted to get the sample changer to below zero temperatures it was observed that while the water bath was getting into the -15 the sample changer was struggling to get to even 0 degrees. This is why me and my colleague was tasked with performing tests on the sample changer and the water baths to try see what the cause was and then figure out a way to fix it.”

They found that the system was consistently unable to reach the expected base temperature, or the expected maximum temperature, despite the water bath indicating it had achieved the set point.

Example results from SANS2D.

“The conclusion we came to was that while the water bath was heating and cooling to the set temperature the sample changer was struggling to reach the anything close to the target temperature. We then went over what could be the cause and we decided the main cause is the difference in the pipes bore sizes restricting the flow of the liquid through the system which in turn reduces the amount of cooling that the sample changer is receiving.”

They experimented with a larger bore size piping and saw a dramatic improvement in the temperature parity.

Updated results from SANS2D after changing bore size.

“As you can see from the results the changes worked successfully so we were able to install the sample changer back onto SANS2D which we connected to the water baths and did a couple quick tests to make sure the pipes didn’t interfere with anything in SANS2D while the platform is moving. Once we had tested this then the sample changer could be used allowing the users to perform there experiment on a wider temperature scale.“

Lucas Ward

“My name is Lucas Ward, and I am a third year mechanical engineering apprentice. I am currently working within the Soft Matter department helping out with daily activities. This has been a four month placement, during which I have learned a large deal of information about ISIS and the instruments and what they do.”

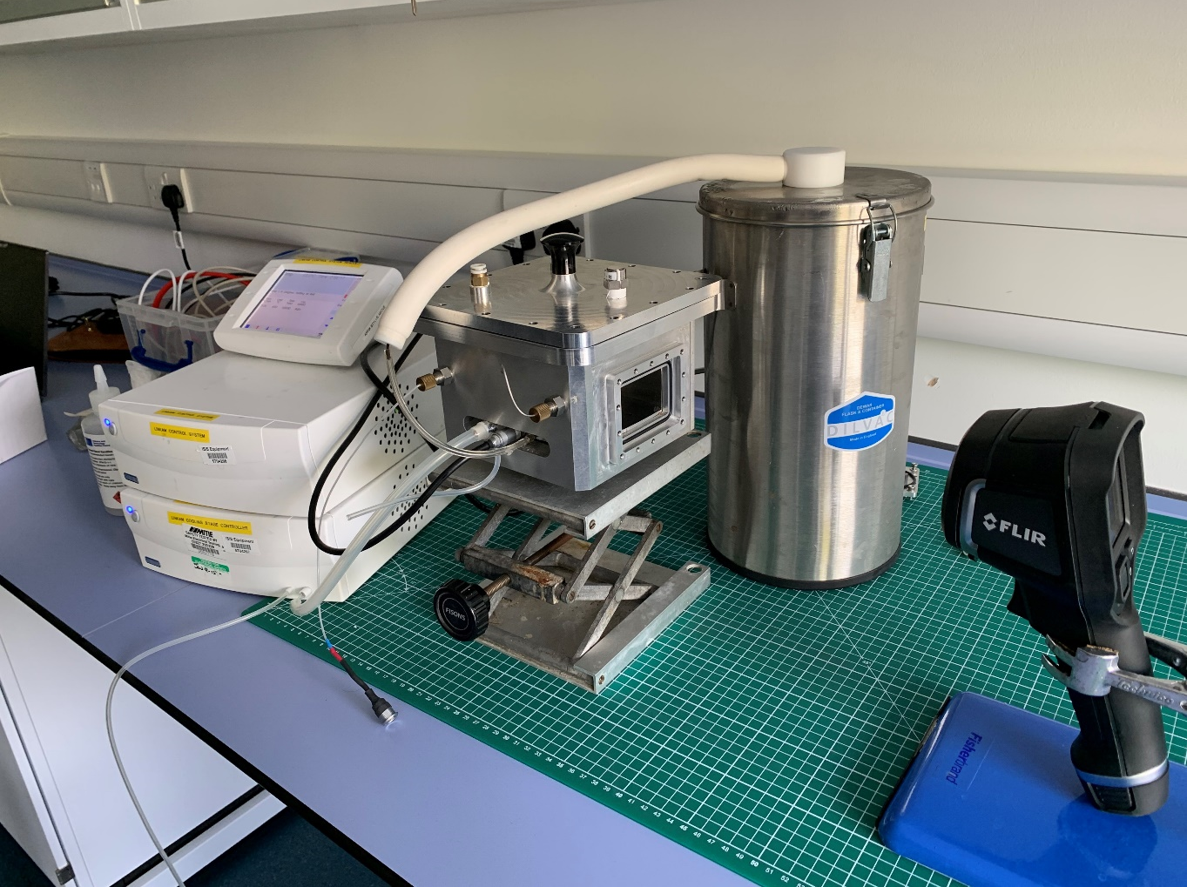

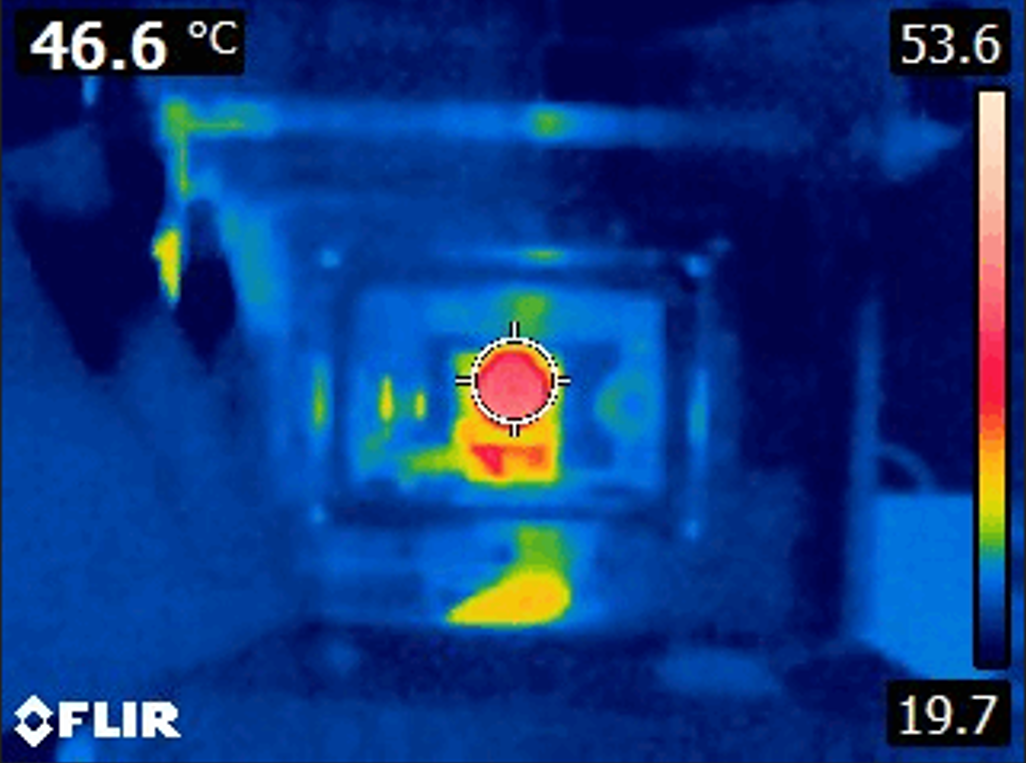

“A unique job I carried out with Soft Matter Technician Matthew Hartley-James was carrying out temperature tests on a Linkam, the job was to show the temperature progression through the Linkam as it heated up.”

Setup for thermal imaging of the inside of the Linkam stage.

Lucas used a thermal imaging camera to observe the equipment as the temperature was varied, taking periodic pictures.

Example data obtained from thermal imaging of Linkam stage.

“After a progression from around 20 degrees to 50 degrees we were left with roughly 65 photos, using an online GIF creator the photos were stitched to create a stop motion video. The video very clearly showed the temperature progression through the Linkam. From this video we could see where the heat propagated from and how it transferred throughout the Linkam. From this Matthew and I were able to confirm that it was heating as expected and that the previous test must have been incorrect.

Using this simple setup and advanced camera we could quickly find out the cause of the anomaly with video evidence. In this specific situation it all was working as it should be so no further action was required.”

Harry Oliver

Harry Oliver was working on a cell holder for the LoKI Small Angle Neutron Scattering (SANS) experiment at the European Spallation Source (ESS).

“During my placement in the Soft Matter department I spoke to my supervisor Andy Church and was tasked with testing 3 new LoKI cell holder configurations to determine which performed the best when heating and cooling. The results of the testing would help influence the choice of cell holder on the LoKI beamline at the ESS.

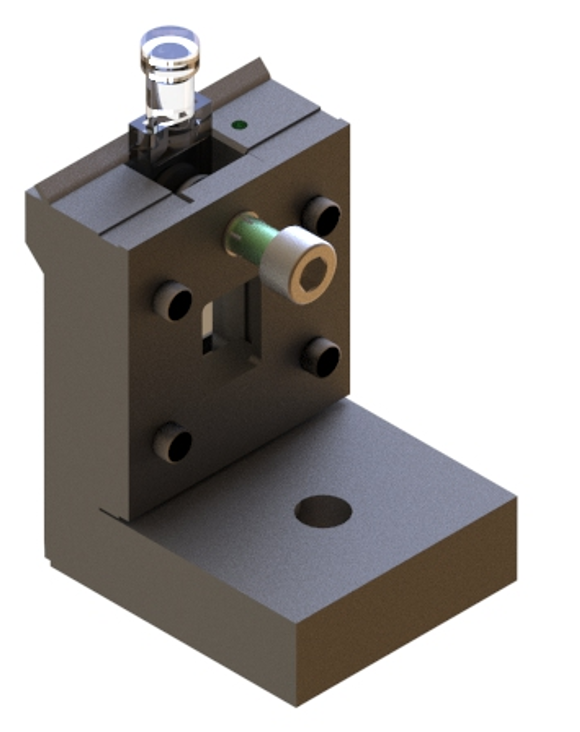

LoKI cell holder.

There were 3 designs tested, including one with a Polyetheretherketone (PEEK) screw, as is currently used at ISIS Neutron and Muon Source, plus an unclamped configuration to use as a baseline. Harry was working to determine the best configuration for the examples. He went on to explain

“The objectives of the experiment were to determine the time for the sample cuvette to reach a stable temperature at each set point and to determine the temperature stability of each cell holder configuration. The best performing configuration could then be determined.”

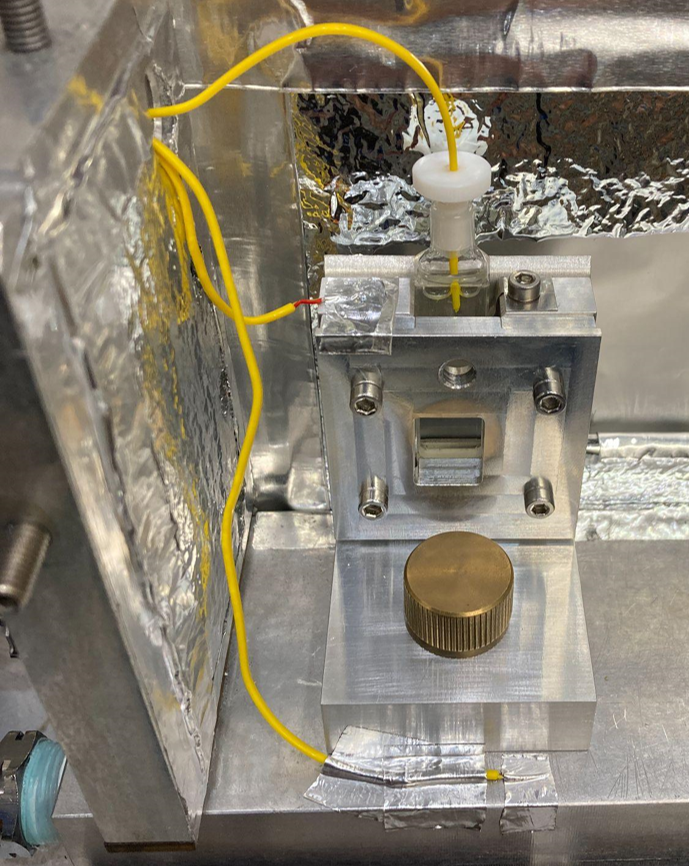

LoKI cell holder during temperature testing.

The experiments were conducted on Zoom, a SANS beamline at ISIS Neutron and Muon Source. Temperature sensors were attached at various positions on the equipment so that differences between the configurations with respect to temperature could be measured. Explaining his findings, Harry said

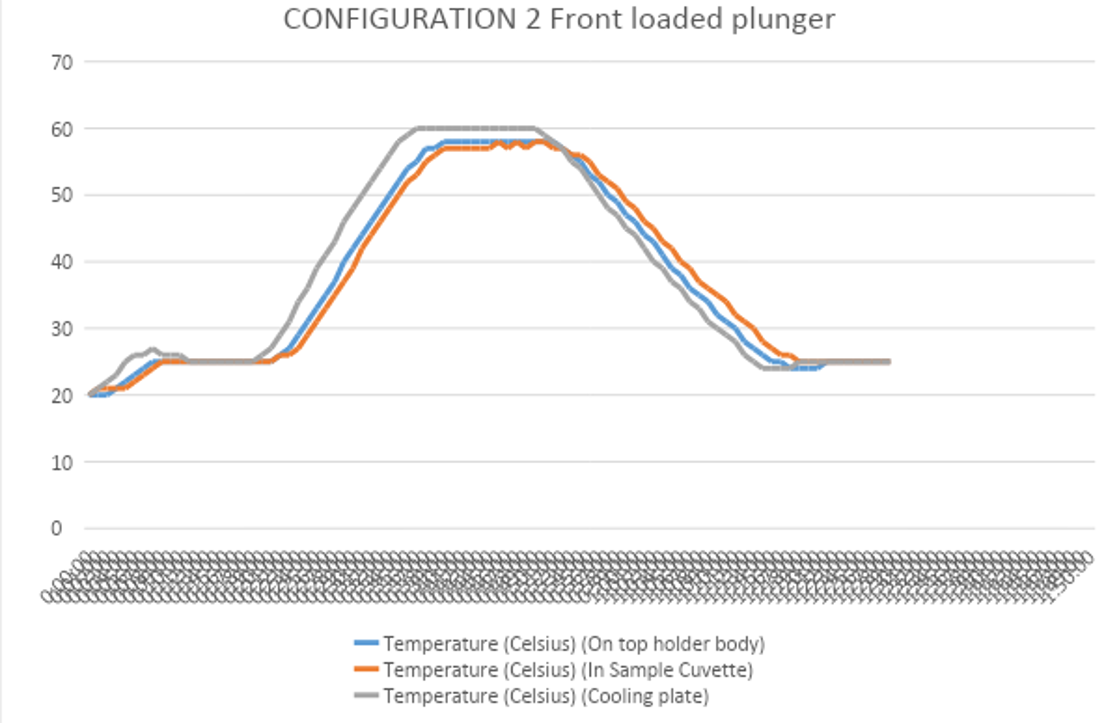

“The results showed that the clamped PEEK screw (Configuration 3) had the overall shortest cycle time but did not heat to 60 degrees as quickly as the cuvette held by the plunger (configuration 2). Overall there were no significant differences between the results. The advantage of the PEEK screw configuration was that this was already being used within the ISIS facilities and meant it would be compatible between facilities.

Looking at the chart below it can be seen that the sample temperature lags behind the cooling plate. This is due to the sample cuvette being made of quartz which does not conduct heat well.”

Temperature comparisons between different positions on cell holder.

For any further details about Soft Matter at ISIS or anything included on this page, please

contact team leader Andy Church and check out the Soft Matter Team

website.