ISIS is the lead partner for two of the instruments being built for the European Spallation Source, a new neutron source under construction in Sweden; FREIA and LoKI. The instruments are currently in the design phase, after which they will be constructed at RAL before being disassembled and shipped to Sweden for installation.

Jacob Simms and Katie Mordecai are working on this project, and Jacob has developed a method of pre-building instruments in a way that allows designers and scientists to see their visions before the instrument is fully installed. This plays a major part in spotting issues and design modifications months before the installation phase and has already been key to the success of the FREIA and LoKI projects and will have even more impact as they continue.

There has already been a lot of interest from other institutes in the project and build documentation that Jacob has employed. He presented his work at the recent virtual DENIM conference: the world's largest and most important conference about Neutron Instrument Engineering.

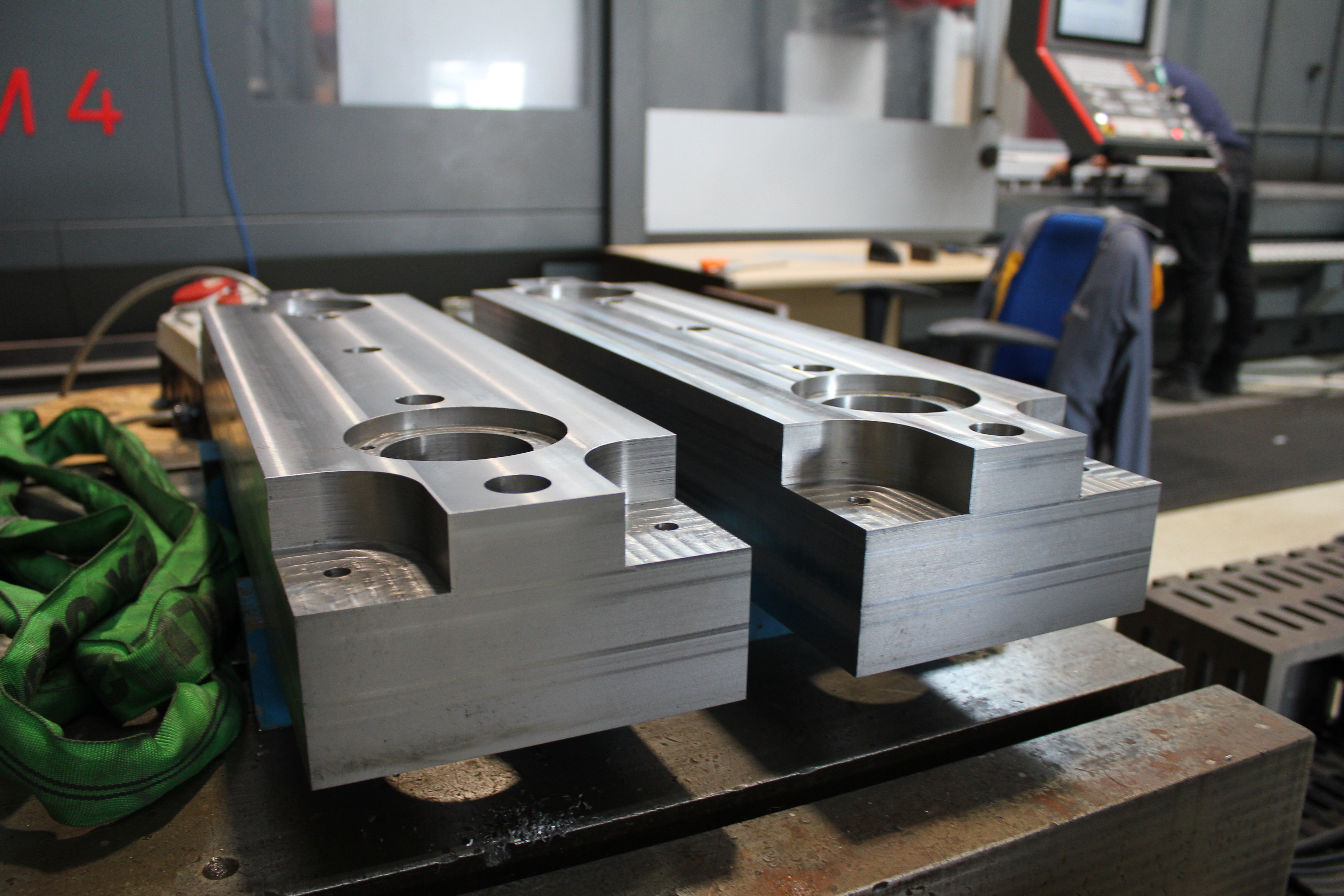

In another area of ISIS, a new milling machine has been installed, which has the capacity to manufacture large pieces of shielding from scratch. This is not only going to be useful for the ESS projects but is already having applications closer to home. Using this machine, technician Jack Osborn is transforming old steel from decommissioned instruments to create shielding for the intermediate shutter project taking place on the ChipIr beamline during the current long shutdown.

Jack finished his apprenticeship at the beginning of September and then joined the team full time. Since then, he has managed to learn the programming system on the new LAGUN machine and implement it to build some key components for the ChipIr project.

Developing the capability to build these components from recycled steel in house not only has an environmental benefit but, during the current global steel shortage, it is particularly important and relevant.

Jack using the new machine, and some of the new components for the ChipIr beamline