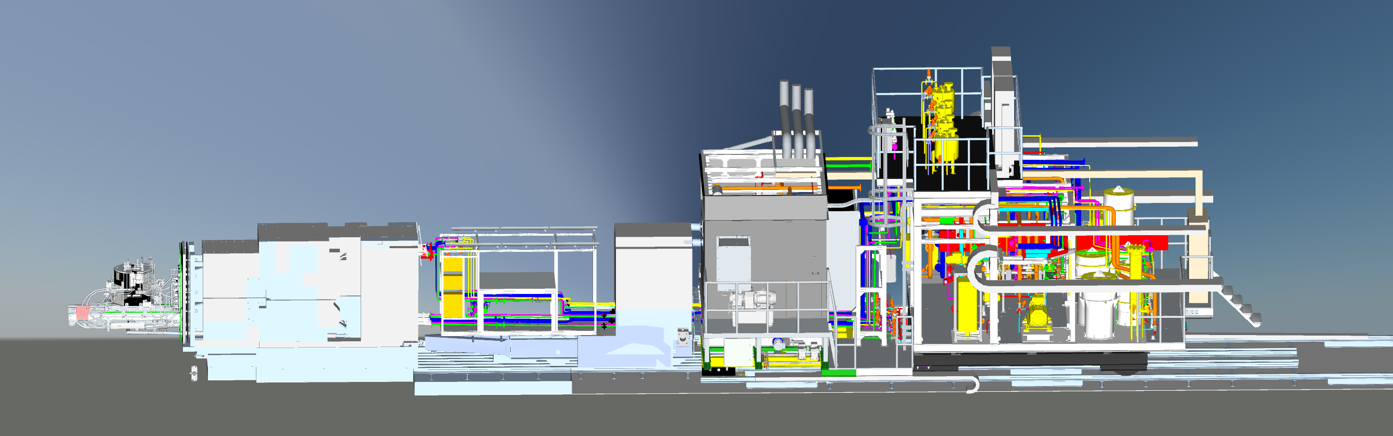

Changing the methane moderator in TS1 involves pulling back the 24-metre long, 400-ton trolley that it sits on. At the front is the target, reflector and moderators (TRaM). In the middle there is a large amount of steel shielding sitting on large trolleys, and to the rear are the cryogenic plants, water cooling circuits and the electrical and control systems. Because of its exposure to high energy protons, the environment around the target is highly radioactive, which makes maintenance in this area very challenging.

The trolley moves back about ten metres to bring the TRaM into the remote handling cell and the middle and rear into the target services area. This normally takes about 20 minutes and needs six tons of force.

Trolley

“On this occasion, however, the trolley became stuck about halfway back," explains Chris Russell, from the Target Operations team. “Upon closer inspection, we discovered that the trolley with the steel shielding on had dropped and was rubbing on its tracks."

The team manually pulled the trolley back with pulling equipment, applying over ten tons of force to get it to move, allowing them to change the moderator. At the same time, the design team created a jockey wheel that bolted onto the trolley, raising it two millimetres above the rails. This enabled the team to begin to move the trolley forwards to its final position.

However, with about 1.5 m to go, the trolley once again stopped and would not move. The team couldn't see any issues, so they again attached the manual pulling gear and, after applying 14 tons, the trolley started to move, taking two hours to get the full way back.

Noticing some fresh scrapes on the north side of the trolley the team used the remote cameras and discovered damage to the stainless-steel wall in the shield tunnel between the void vessel and the remote handling cell (RHC). As there should be clearance between the trolley and the tunnel, scraping showed evidence of contact between the two. They traced it back to a 80 mm diameter pin sticking out by just 6 mm, which had torn the stainless-steel liner.

This damage was in an area that people cannot enter due to the radiation levels. It was also out of reach of the manipulator arms and could not be seen from the RHC windows, so the team were relying on black and white cameras to see the problem.

Solution

The design team first had to dig into the archives to find the original drawings and photographs from the early 1980s that showed the inside of the damaged shield tunnel. None of it was modelled and very little information was available. The team was working to a tight timescale to ensure ISIS would be operational in time for the September user cycle, meaning they had just two weeks to create a fully modelled solution and provide drawings.

Following a consultation with collaborators at the UKAEA, the team decided to use in-house expertise to design a bespoke solution to cut the damaged wall away with grinders.

“Meanwhile, we were building a full-sized replica of the damaged wall section, including the railway tracks, and aligning it to the area used for remote testing," says Chris.

The proposed solution would need a bespoke Power Distribution Unit to remotely operate up to four grinders, four lights and a vacuum cleaner, which was built and delivered by Jamie Nutter and the EEUSG group in just a few days.

The controls group were building motor controllers so the targets team would be able to drive the grinders in three directions from the safety of the manipulator rooms.

Mock build testing

As the designs were signed off, they were sent to various machine workshops across ISIS, as this was much quicker than using outside manufacturing, and everyone was keen to assist.

By week three, the teams were starting to assemble the components. Their design consisted of a rear trolley, complete with electric four-wheel-drive, and a front trolley with grinders mounted onto the front of it. The trolleys also had camera holders, cable management and a piece of rope to retrieve the trolley should something go wrong!

As the components were being delivered, the team were tweaking their design, either to improve performance or to aid with remote handling. In some cases, they redesigned complete assemblies.

By week six, the team were running full scale rehearsals of every task, from loading the RHC to making the cuts.

Repair

Repair

In week seven, the real repair began. It took a full day to remotely crane components into the RHC. A further two days were spent assembling mechanical components and pulling and connecting all the cables.

The cutting itself required careful coordination between a team of seven people operating the trolley, the grinders, the cameras and the electrics.

Removal

“The final stage was to remove the damaged section of wall, and something we could not simulate on the mock-up," explains Chris. “We had no information on how the steel was joined to the wall and had to look carefully at the original photographs and remote camera shots we'd been able to get hold of. After it put up some resistance, we finally removed the damaged section."

The team were still short of time, so the cleanup began almost straight away. Disconnecting the cables and separating the two trolleys gave the space needed to remove the damaged section of wall. All the equipment used was cleared off the tracks and stored either side of the RHC, ready to be removed in the January shutdown.

The final task was to drive the trolley forward into its fully forward position. Lots of fingers were tightly crossed, but this time it went smoothly.

“We owe a big thank you to all involved with this repair," adds Chris. “It was a great team effort from many people, completing a complex remote repair in eight weeks."